[vc_row][vc_column][vc_column_text]

MACHINE POLISHING WITH BAR ROUGE

EQUIPMENT AND SUPPLIES NEEDED

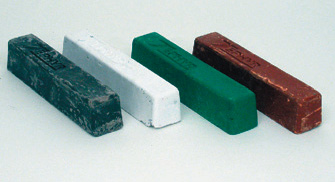

BAR ROUGE

COMMONLY USED:

87 Stainless

TR-2 Brown Tripoli

Green Chrome

White Chrome

POLISHING WHEELS:

AWR – Red Airway

AWY – Yellow Airway

AWp- Purple Lea Airway

AWW – White Airway Untreated

COTTON MUSLIN BUFFS:

30 Ply

40 Ply

50 Ply

60 Ply

SANDER / GRINDER MACHINE:

3,000 – 6,000 RPM

PRO-40 PERFECTION METAL POLISH

MICROFIBER POLISHING TOWELS

SAFETY FIRST:

Always use safety flanges with any buffing wheel that has a metal center plate.

Step1: SAFETY FIRST

Screw the threaded extender onto the machine spindle. Make sure the extender is securely tightened on the spindle.

Lay the flat flange on the end of the extender.

Place the Airway Buffing Wheel on the flat flange.

Place the concave flange over the Airway Buffing Wheel so that the raised part of the flange fits into the hub of the buffing wheel.

Place the concave washer, flat side down, into the recess of the concave flange.

Use the flathead bolt and a 3/8” hex wrench to securely tighten the safety flange assembly and Airway Buffing Wheel to the extender and machine spindle.

For safety, always wear a respirator and face shield or goggles.

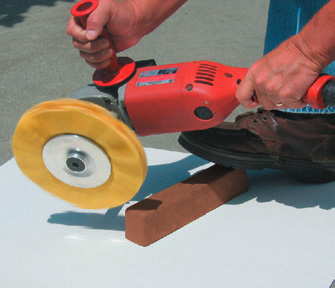

Step2: Using Rouge Bars

The 87 Stainless Rouge Bar is used for heavy cutting iron, steel, aluminum, and stainless.

The TR-2 Brown Tripoli Rouge Bar is used for primary cutting stainless and aluminum.

The Green Chrome Rouge Bar is used for secondary cutting, semi-final finish, stainless and aluminum.

The White Chrome Rouge Bar is used for a final finish, high luster, stainless, and aluminum.

Step3: START THE POLISHING PROCESS (CUTTING)

For safety purposes, hold the rouge bar down firmly on the ground with your foot. Touch the rouge bar with the outside edge of the rotating buffing wheel until the rouge adheres to the wheel. The rouge bar should be placed on white paper or cloth to keep it clean.

Start at one end of the fuel tank. Use TR-2 Brown Tripoli or Green Chrome rouge and Yellow Airway Cutting Wheel.

The shine is created by letting the buffing compound do the cutting and polishing, not by how much pressure is applied against the metal surface. Polish your fuel tank by sections. Start from the top or bottom. Use a smooth left to right polishing motion. Make several passes to create a clean shine, using overlapping motion.

Step4: CLEANING AND FINISHING

Replace the cutting wheel with a white finishing wheel and use the same basic motion and direction as the cutting process.

Step5: FINAL WIPE DOWN

After cutting and finishing, the tank is still dusty and pores filled with caked oxidation residue. To remove without marring the finish, apply liquid PRO-40 PERFECTION METAL POLISH with MICROFIBER TOWEL. Rub until the surface becomes dark. Let dry and wipe off to a clean brilliant shine with a soft, dry MICROFIBER TOWEL.[/vc_column_text][/vc_column][/vc_row]